Raise Your Voice! Navigating and getting involved in the mining review process

Raise Your Voice

Navigating and getting involved in the mining review process

Written by Tali Pukier, 2025 Conservation Intern | July 16, 2025

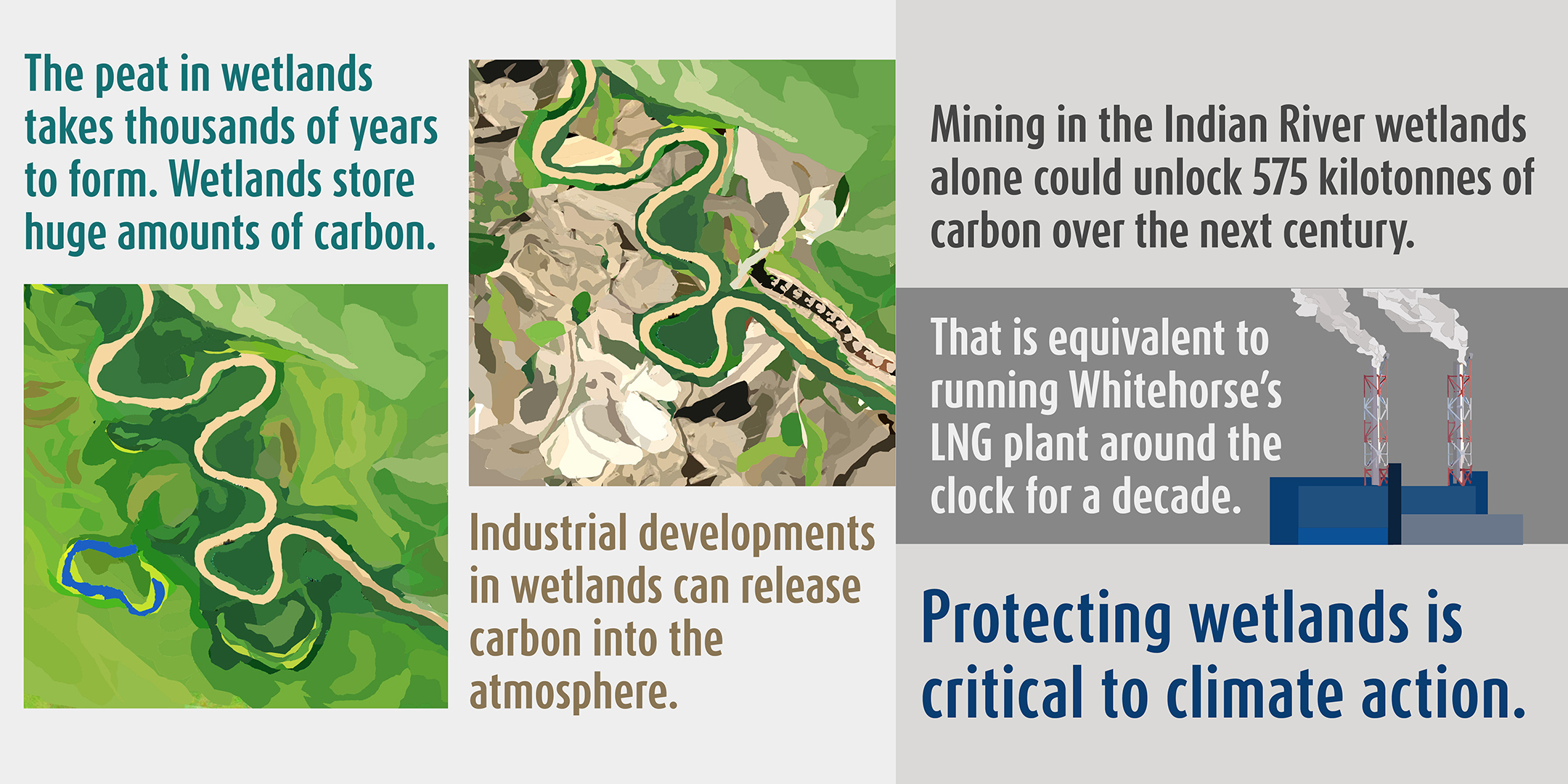

For those who have been in the Yukon for millenia or months, the impact of mining in the territory is hard to miss. The legacy of the Klondike Goldrush is seen and felt across the landscape. Abandoned dredges, mine shafts, and old camp sites dot the territory, while unseen contamination from failed mines leaves people unable to trust the land.

Mining projects move through the regulatory system every day, from exploration proposals to water licenses and inspection reports, to closure and remediation. Although information about mining projects in the Yukon is publicly available, it’s hard to find—and even harder to understand! Knowing what’s happening with these projects is an important part of having a say in mining in your community and across the territory.

This guide dives into where to access information, at all stages of a project’s lifetime, as well as how and when you can share your opinion about proposed and active mining!

Step 1

Impact Assessment

Submit a comment through YESAB during a two week window.

Step 2

Step 2

Water License

Submit a comment through Waterline or attend a public hearing.

Step 3

Step 3

Land Use Permit

Stay up to date on permits through the Mining Land Use Registry.

Step 4

Monitoring and Inspection

Check in on mining operations through their monitoring and inspection reports.

Why should I care about mining projects and regulations?

Public consultation is all about asking you what you think and want. It’s an essential part of the mining review and regulation process. When people like you participate in comment periods and public hearings, project leaders and government officials use the public’s opinion to help decide if a project should go ahead or not, and how it should operate if it does.

When Yukoners don’t participate, mining companies and regulators aren’t being watched by the people and communities their projects will affect.

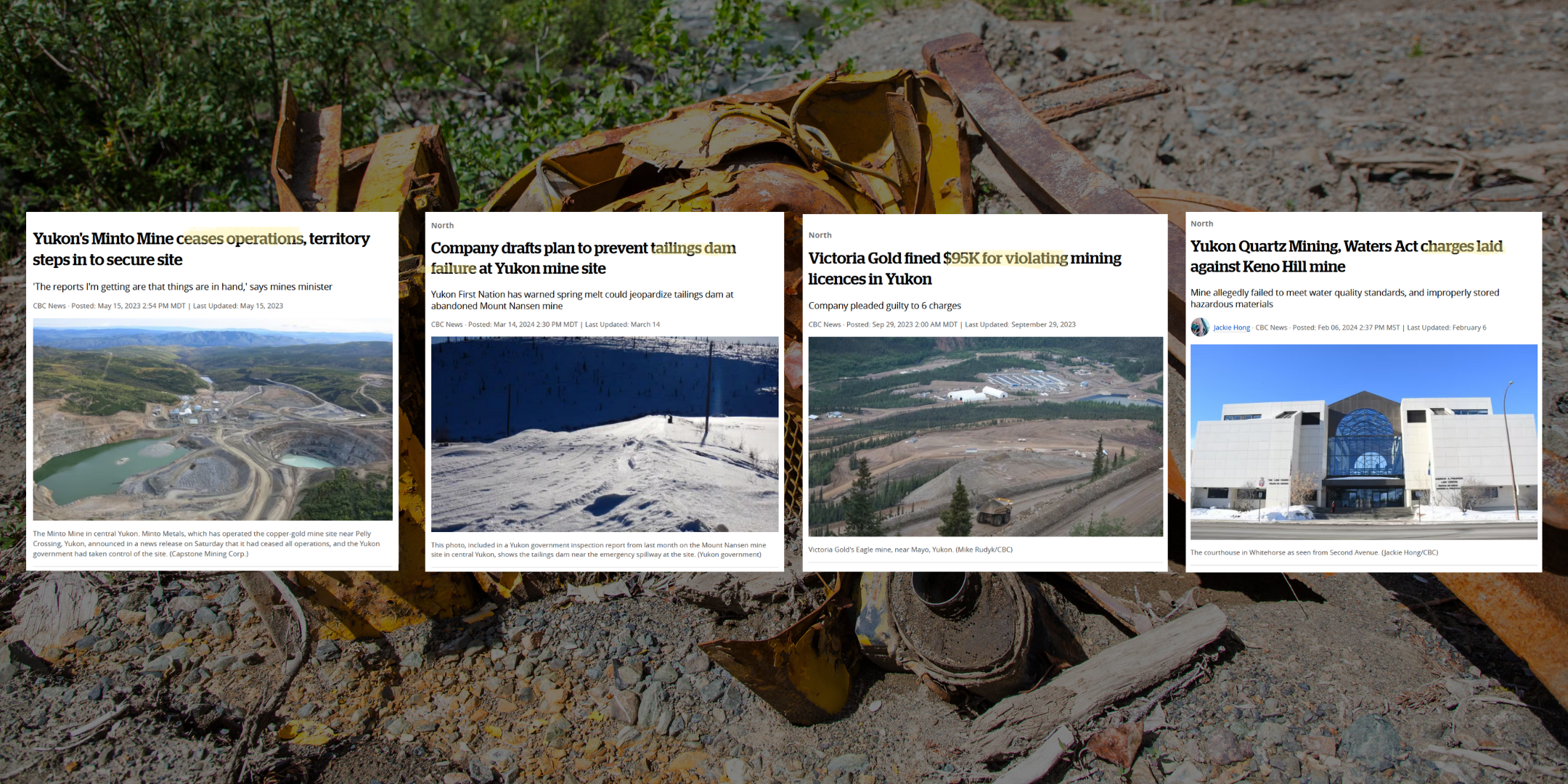

This can lead to complacency at all levels when projects are proposed without properly considering changing environmental and social factors. Complacency opens the door to accidents, mismanagement, and even environmental disasters like the Eagle Mine heap leach failure that began in June 2024.

Your opinion matters and can be shared at more than one stage of the project review process.

Step 1: Impact Assessment

YESAB stands for the Yukon Environmental and Socio-economic Assessment Board. Proponents, the people or companies that want to mine in an area, submit an application to YESAB, which does impact assessments and recommends changes to projects. YESAB does not issue development permits, but their assessments are a key step in mining review. They consider environmental and social values and give the public a chance to share their opinion on the effects of mining in the region.

Once an assessment is complete, YESAB issues a recommendation of whether a project should or should not go ahead, to the Decision Body, which is typically the Yukon government. When proposed projects are on First Nations Settlement Lands, the First Nation is the Decision Body.

It’s important to know that YESAB was born out of the Umbrella Final Agreements, signed between eleven Yukon First Nations, the Yukon government, and the Government of Canada. Unceded Yukon First Nations (Liard River First Nation, Ross River Dena Council and White River First Nation) never signed onto the treaty, but projects in their traditional territories must go through YESAB regardless.

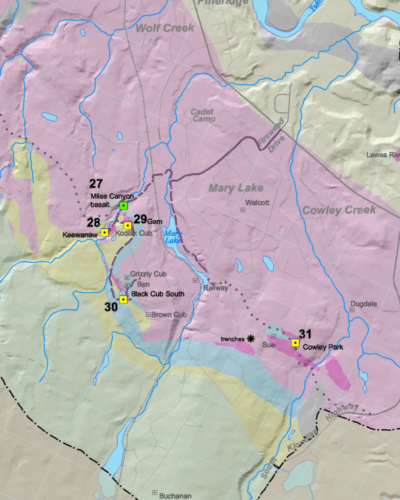

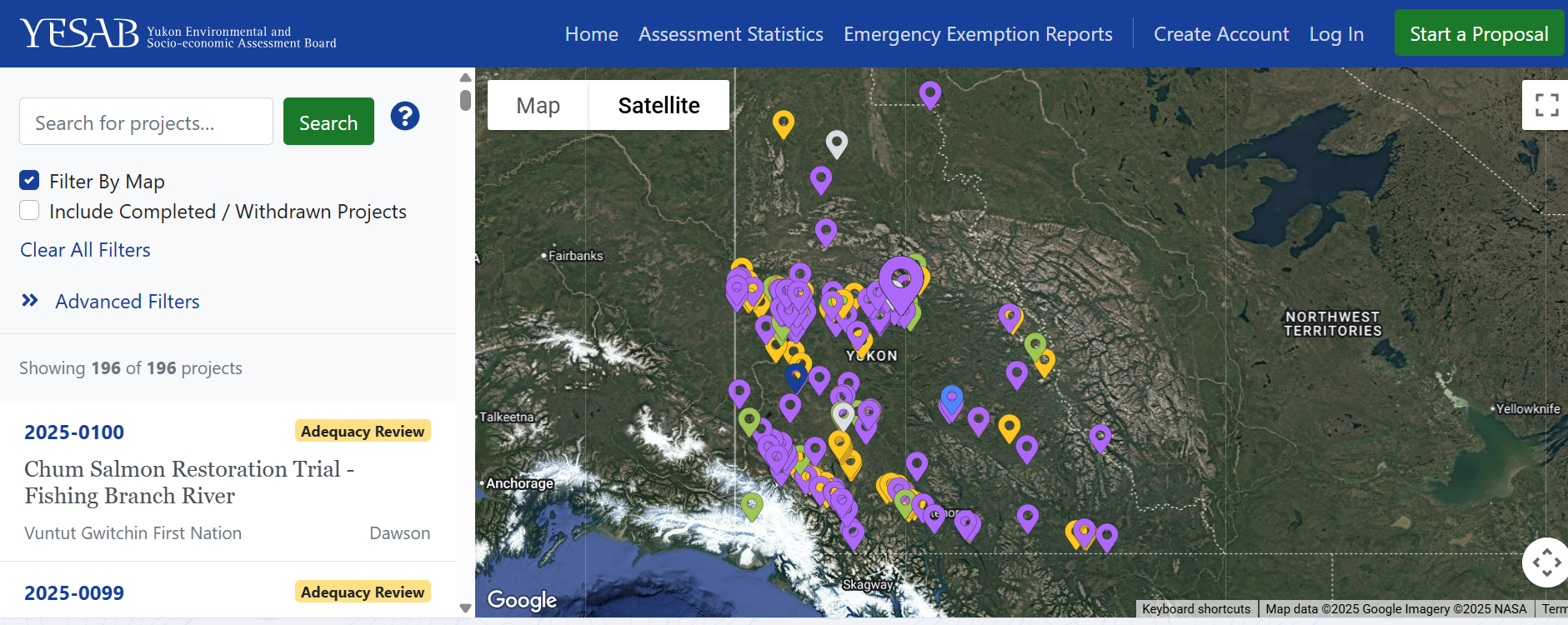

If you would like to know more about what projects are being proposed in the territory, check out the YESAB Registry. The map that comes up shows projects currently being assessed at YESAB.

TIP: To stay informed about all projects in one area, you can select a boundary of interest and receive notifications about all projects.

Where to find documents in YESAB

Project Proposals that outline initial commitments made by the proponent can be found in the Documents tab. But commitments can change, and updated information is uploaded under amended versions of proposals.

Comments are found in a separate Comments tab and show what others have said about the project.

Evaluation Reports, the official recommendations made by YESAB, are found in the Documents tab.

YESAB makes recommendations that are accepted or rejected by whoever issues the mining land use permit. If YESAB recommends that a project go ahead and that recommendation is accepted by Yukon government, proponents must apply for a water license with the Yukon Water Board.

Step 2: Water License

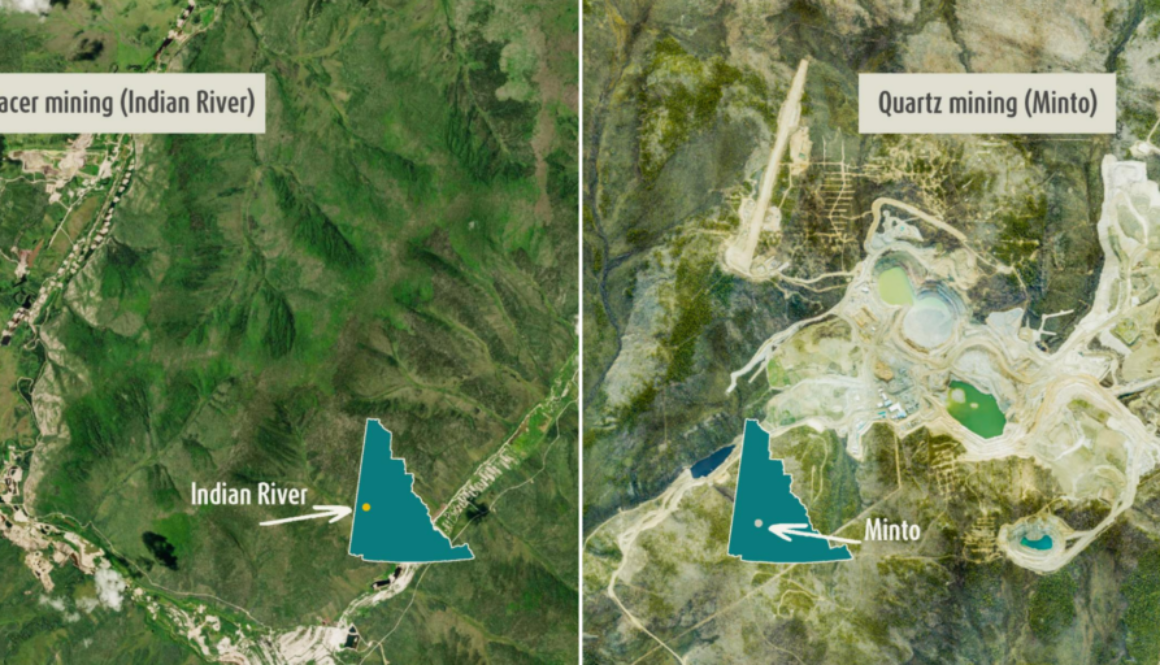

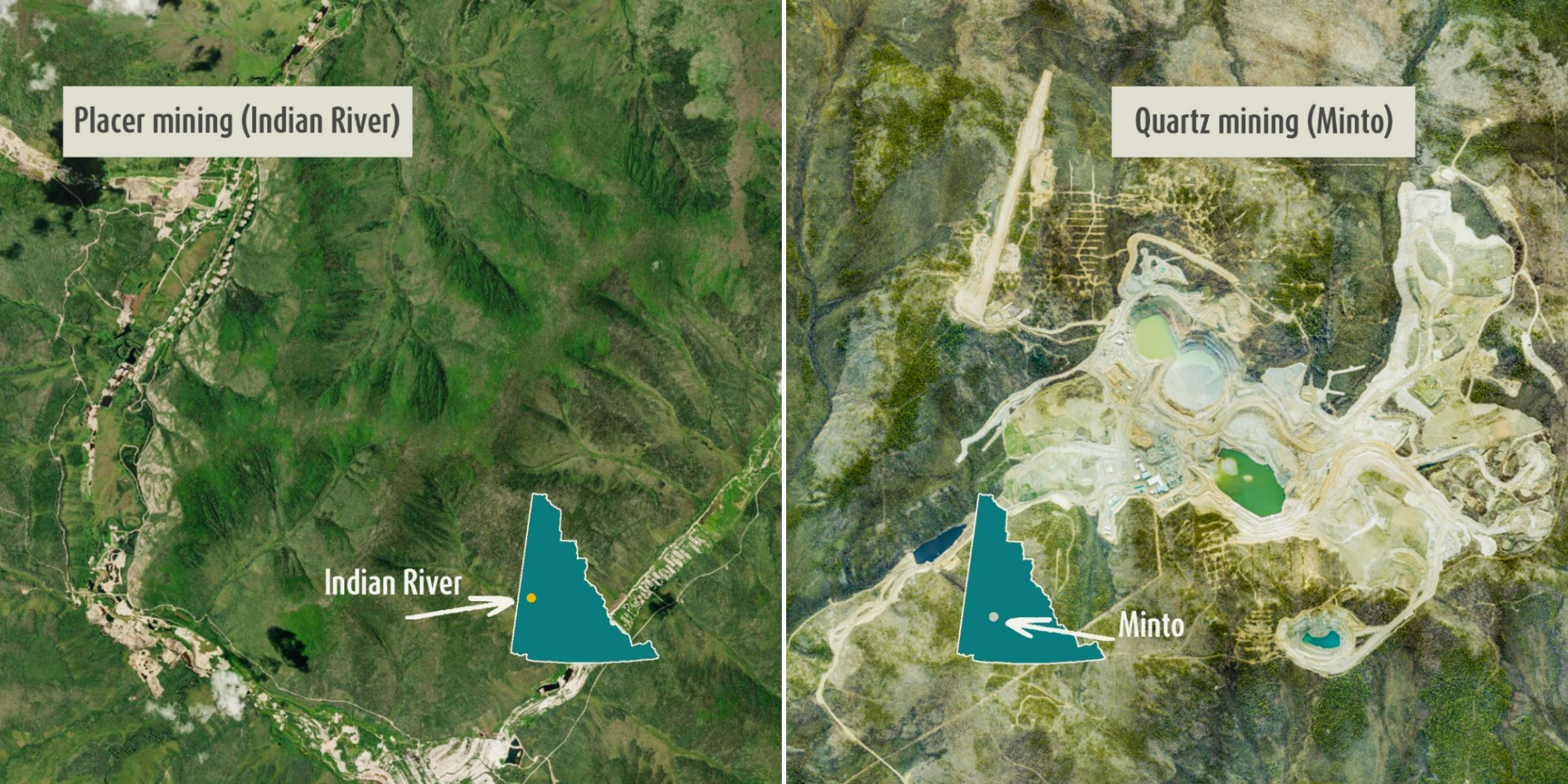

The Yukon Water Board reviews applications and issues water licenses on Waterline. Activities that require a water license are described in Schedule 2 of the Yukon Waters Act and include both placer and quartz mining activities. These water licenses must be followed by proponents. What they say goes!

The Water Board considers water-related feedback from the public, so be sure to centre water when you share your thoughts.

TIP: If you don’t want to create an account and just want to browse licenses and applications, you can login to Waterline as a Guest (on the bottom right of the web page).

TIP: Sometimes, licenses and company names change. When a license is updated or amended, an additional number is added to the file number (e.g. 2025-XXX becomes 2025-XXX-1), and the Submission Type will say “Amendment.” If you are searching for a past project by company name, make sure to use the name that was used when the license was originally submitted.

Where to find documents in Waterline

The Application tab includes information about water usage and mining design.

The Interventions tab posts comments made by the public.

The Pre Hearing Conferences and Public Hearing tab has transcripts from public hearings.

Step 3: Land Use Permit

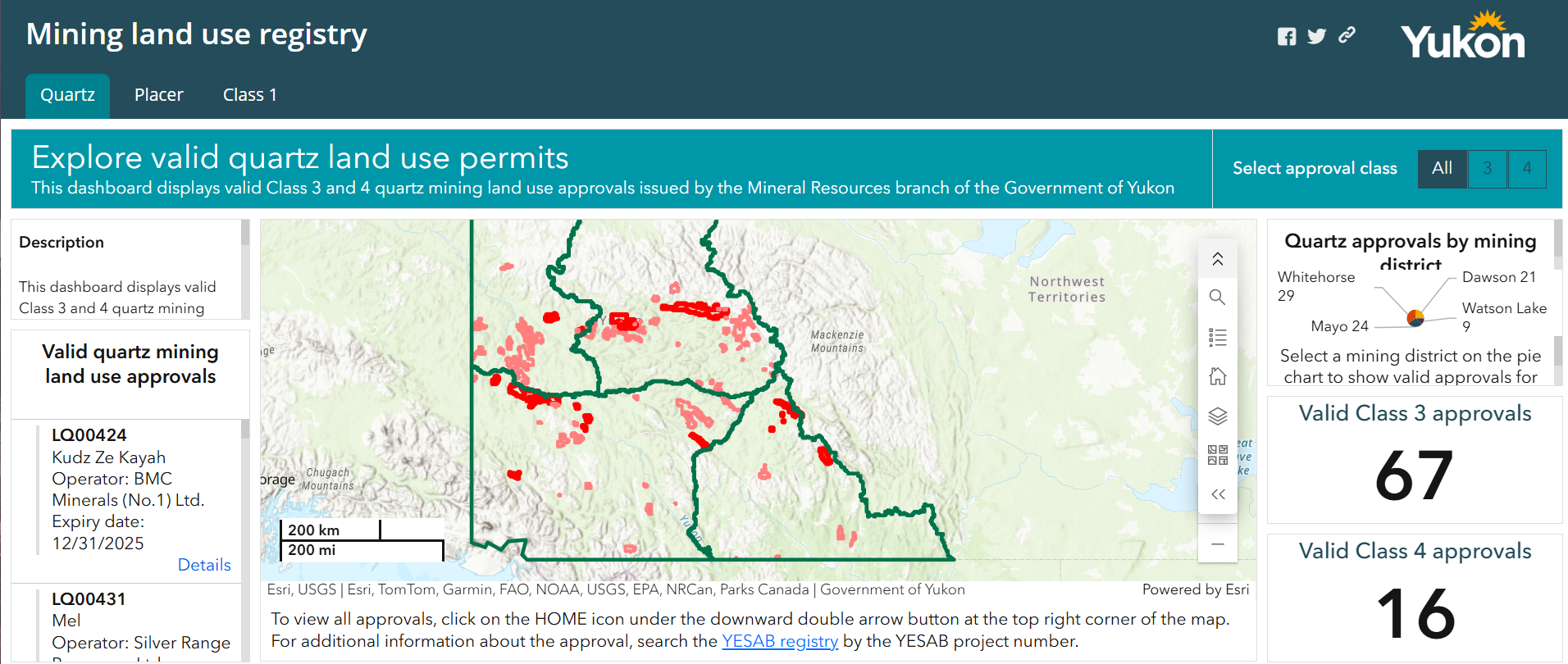

The third step in the mining review is getting a mining land use permit. Mostly, it is the Department of Energy, Mines and Resources at the Yukon government that issues the permit, but a First Nation has that power if the project is on Settlement Lands. The Mining Land Use Registry shows all the mining land use permits in the territory.

Step 4: Monitoring and Inspection

Compliance, Monitoring, and Inspection (CMI) Officers check in on mines to ensure miners are abiding by the rules set out in their mining land use permits. Inspection reports show whether mining operations are doing what they said they’d do and following their permits. If reports show that mine operators haven’t been following the rules of their permit, it is up to the Yukon government to impose warnings, fines, or revoke their permit.

Reports are uploaded to Waterline, in the Reports section of the Menu (on the left side). Miners do their own reporting too, which are also found under Reports.

Other Resources

- The Yukon Government is in the middle of creating new Mineral Legislation for the Territory. The report from their 2023 public engagement is available here.

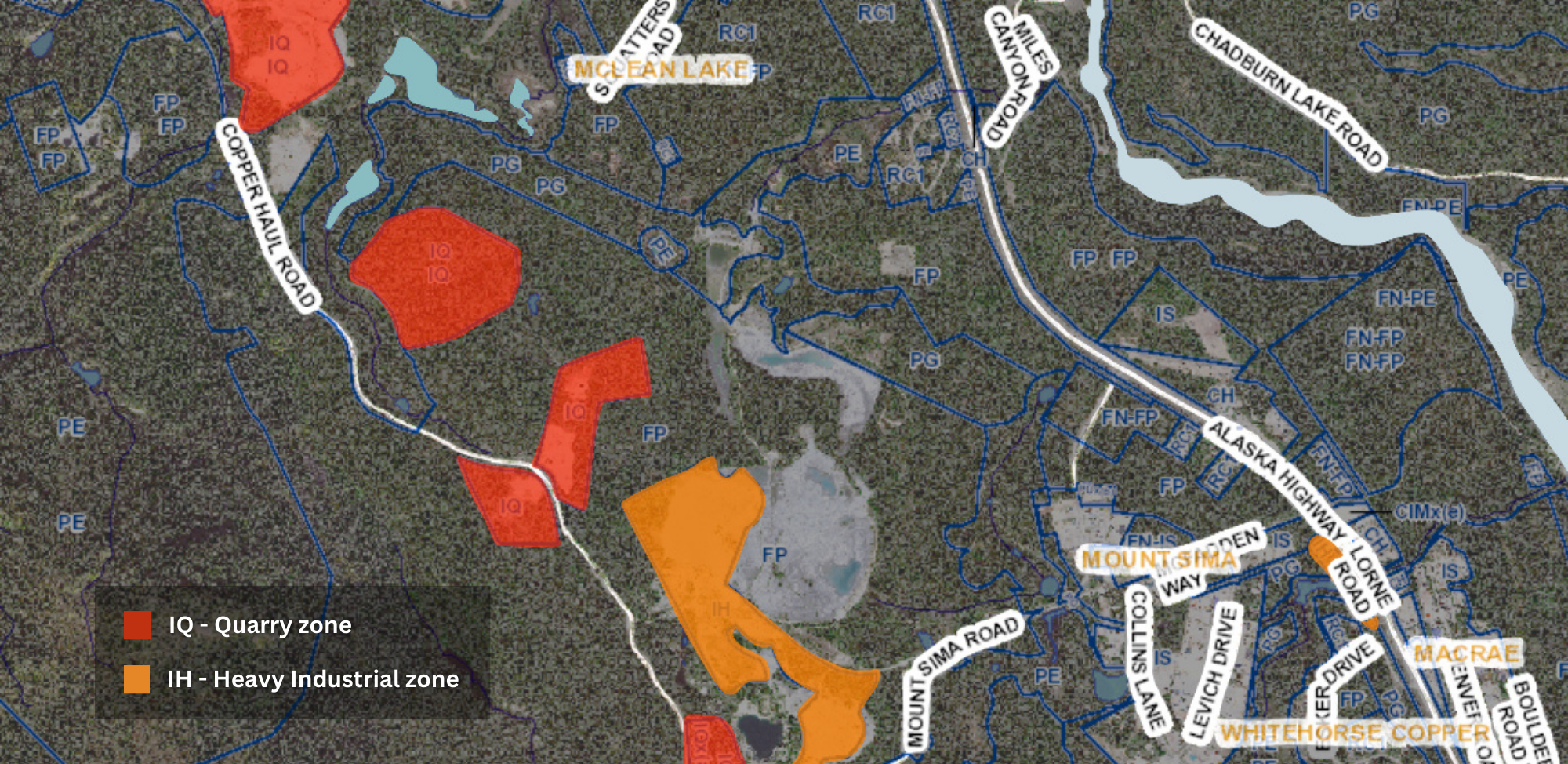

- Geo Yukon is an interactive mapping tool. Click on layers in the left-hand column to see information related to development in the Yukon. Clicking the Mining, Quartz Activity, and Land Tenure categories show the thousands of placer and quartz claims across the Territory, and who operates the claims.

- The Energy, Mines and Resources Library has thousands of online and in-person records about mining development and review. Browse their online catalogue or stop by to talk to someone in person. The library is located at the Elijah Smith building on Main St. The library is open 8:30am – 4:30pm Monday through Friday.

- Yukon News, CBC North, and APTN News cover mining in the Yukon. Search for “Mining” in their search bar to filter for articles about mining in the territory.